Powder Coating Services: Durable, Eco-Friendly Metal Finishing Solutions

At An Thanh, a leading powder coating specialist based in Vietnam, we deliver high-quality electrostatic powder coating services for international clients. Our expertise covers industrial components like J-hooks, steel frames, turnbuckles, crane hooks, and custom mechanical parts—ensuring superior protection and aesthetics for global markets.

What is Powder Coating? Complete Overview

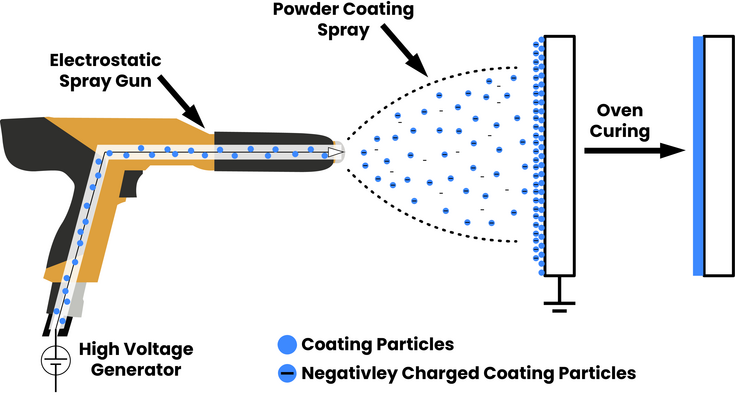

Powder coating is the process of applying finely ground dry powder to metal using electrostatic charge, followed by high-temperature curing (180-200°C) to create a seamless, hard finish. Unlike wet painting, it contains no solvents, eliminating VOC emissions and drips for a cleaner, more consistent result.

The professional powder coating process consists of four key stages:

- Surface Preparation — Thorough cleaning via sandblasting or chemical treatment to remove rust, oil, and contaminants.

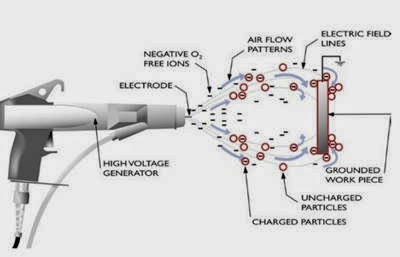

- Electrostatic Spraying — Powder is charged and attracted evenly to grounded parts using specialized spray guns.

- High-Temperature Curing — Parts are baked in precision ovens to melt and bond the powder into a durable skin.

- Quality Assurance — Testing for thickness (60-100 µm), adhesion, gloss, and impact resistance.

Step-by-step process illustrations:

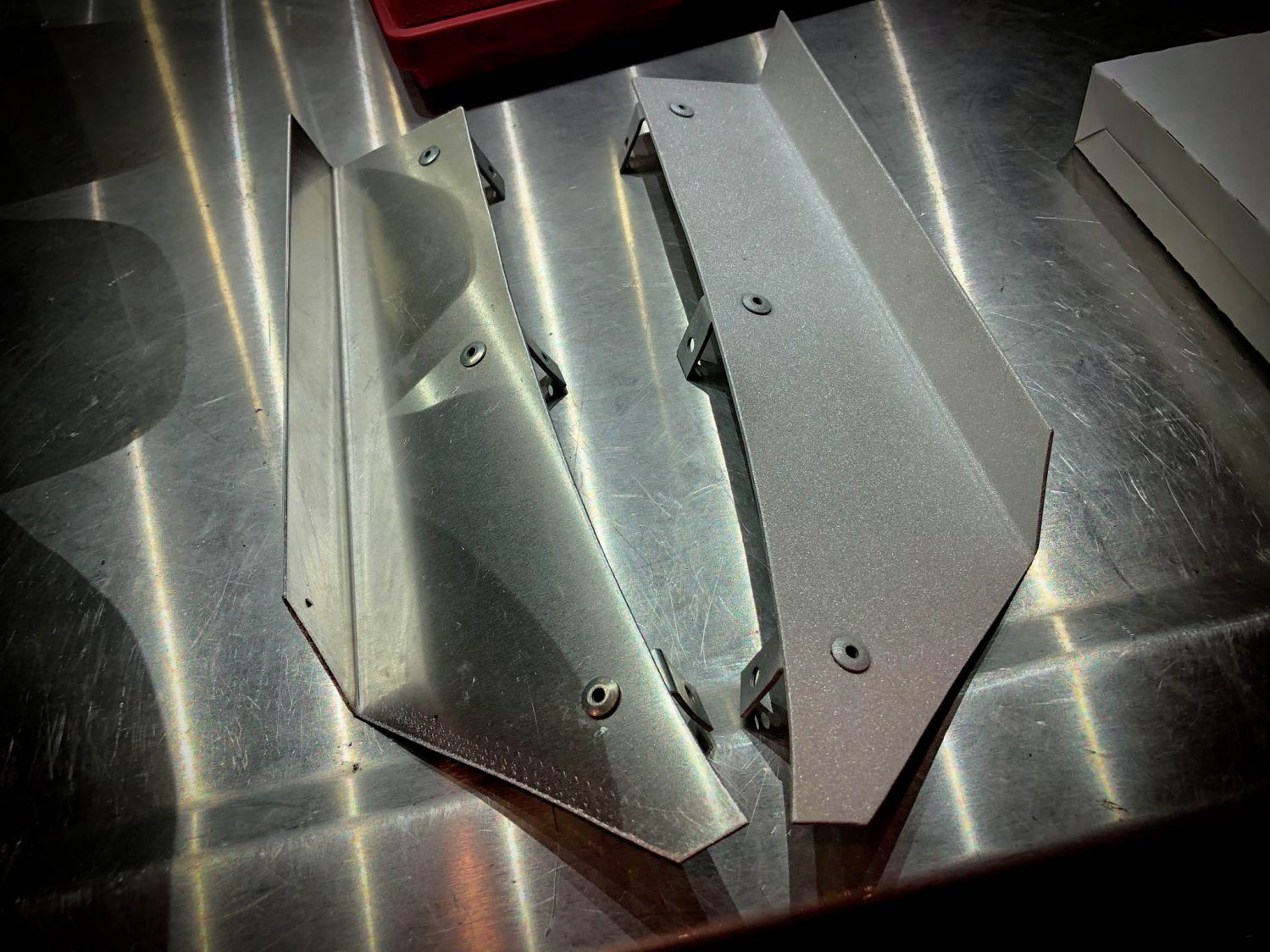

Common Applications of Powder Coating

Powder coating is widely used across industries for its superior performance:

- Industrial & Manufacturing → Machinery housings, steel structures, cargo lashing hardware (J-hooks, ratchet buckles), and automotive parts.

- Construction & Architecture → Railings, gates, window frames, and structural steel.

- Consumer Goods → Metal furniture, appliances, bicycle frames, and electronics enclosures.

- Marine & Outdoor → Excellent corrosion and UV resistance for harsh environments.

Before-and-after examples:

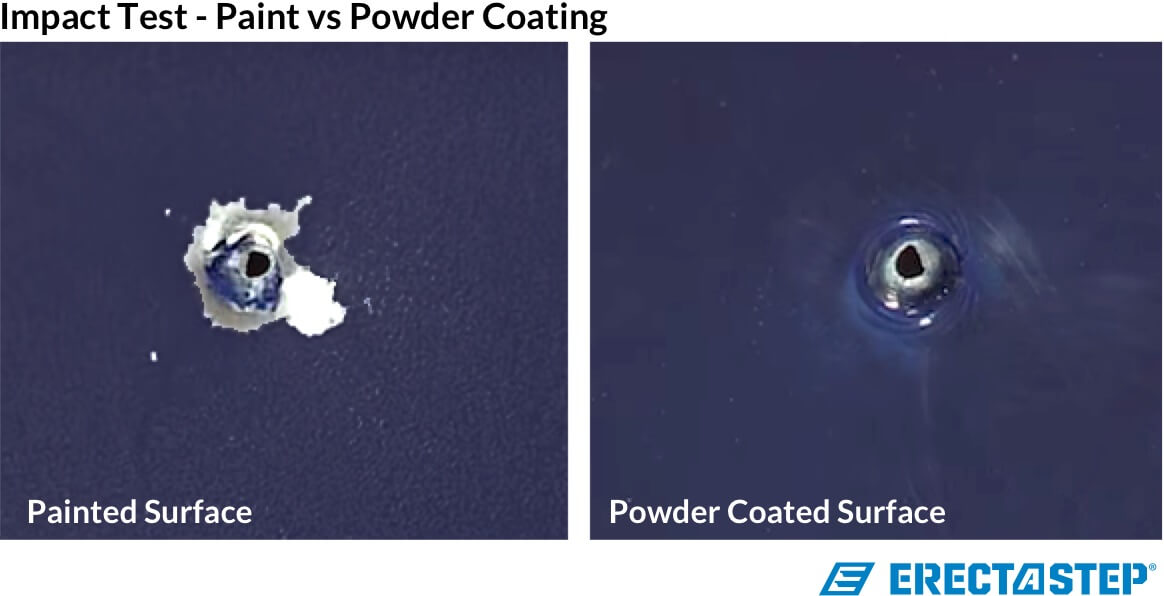

Powder Coating vs Traditional Wet Painting: Why It’s Superior

Powder coating offers clear advantages over conventional liquid paints:

- Exceptional Durability → Resists chipping, scratching, fading, and corrosion—lasting 10-20+ years.

- Environmentally Friendly → Zero solvents, recyclable overspray, low waste.

- Cost Efficiency → Higher transfer efficiency, thicker single-coat application, reduced maintenance.

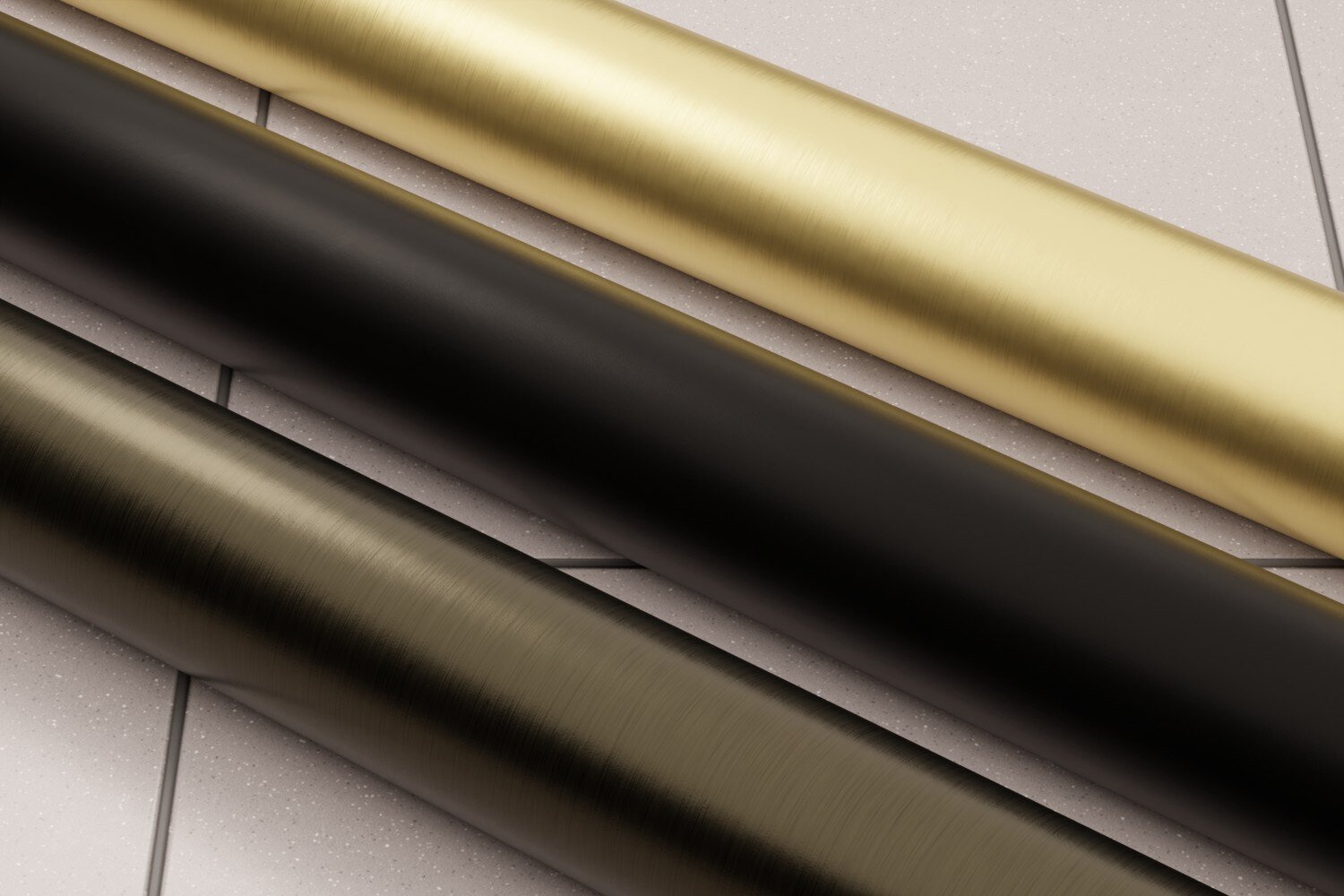

- Aesthetic Excellence → Smooth, uniform finish with no runs; available in countless colors and textures.

- Performance → Superior chemical, heat (up to 200°C), and UV resistance.

Comparison visuals:

Powder Coating Costs and Pricing Factors

Pricing varies based on part size, complexity, material, powder type, and order volume. Typical industry rates:

- Standard colors: $3–6 USD per kg

- Premium/specialty (anti-corrosion, high-heat, textured): $7–12 USD per kg

Additional factors:

- Surface preparation (blasting/phosphating)

- Masking for complex designs

- Volume discounts for bulk orders

An Thanh provides competitive international pricing with transparent quotations.

State-of-the-Art Technology at An Thanh

Our modern facility features:

- Advanced electrostatic spray systems for minimal waste

- Automated conveyor lines and large-capacity curing ovens

- High-quality powders from global brands (AkzoNobel, TIGER, Jotun)

- Full pre-treatment systems for maximum adhesion

We comply with international standards (ISO, Qualicoat) for consistent, export-ready quality.

Why Choose An Thanh for Global Powder Coating Services?

- Proven expertise in industrial hardware and custom projects

- Competitive pricing with reliable lead times

- Export experience and international shipping support

- One-stop solution: From fabrication to finishing

- Dedicated customer service in English

Frequently Asked Questions About Powder Coating

- What is powder coating? A dry, electrostatically applied powder cured by heat for a tough, attractive finish.

- How does the powder coating process work? Preparation → Spraying → Curing → Inspection.

- What are the main benefits over liquid paint? Greater durability, eco-friendliness, better finish, and lower long-term costs.

- What products are suitable for powder coating? Most metals: steel, aluminum, galvanized steel—ideal for hardware, frames, and machinery.

- How long does powder coating last? 10–20+ years with proper application and maintenance.

Contact An Thanh for Professional Powder Coating Worldwide

Looking for reliable, high-quality powder coating services for your international projects? Get in touch today:

- Phone: +84 942 127 028

- Email: cokhi.anthanhtech@gmail.com

- Website: anthanhtech.com

An Thanh—Your trusted partner for premium powder coating solutions delivered globally!

There is no products in this list