Lashing buckles, metal triglide buckle, tri glide buckles, tri glide slide buckle, tri glide slides | Top 1 Lashing Buckles Factory in Vietnam

Types of Lashing Buckles

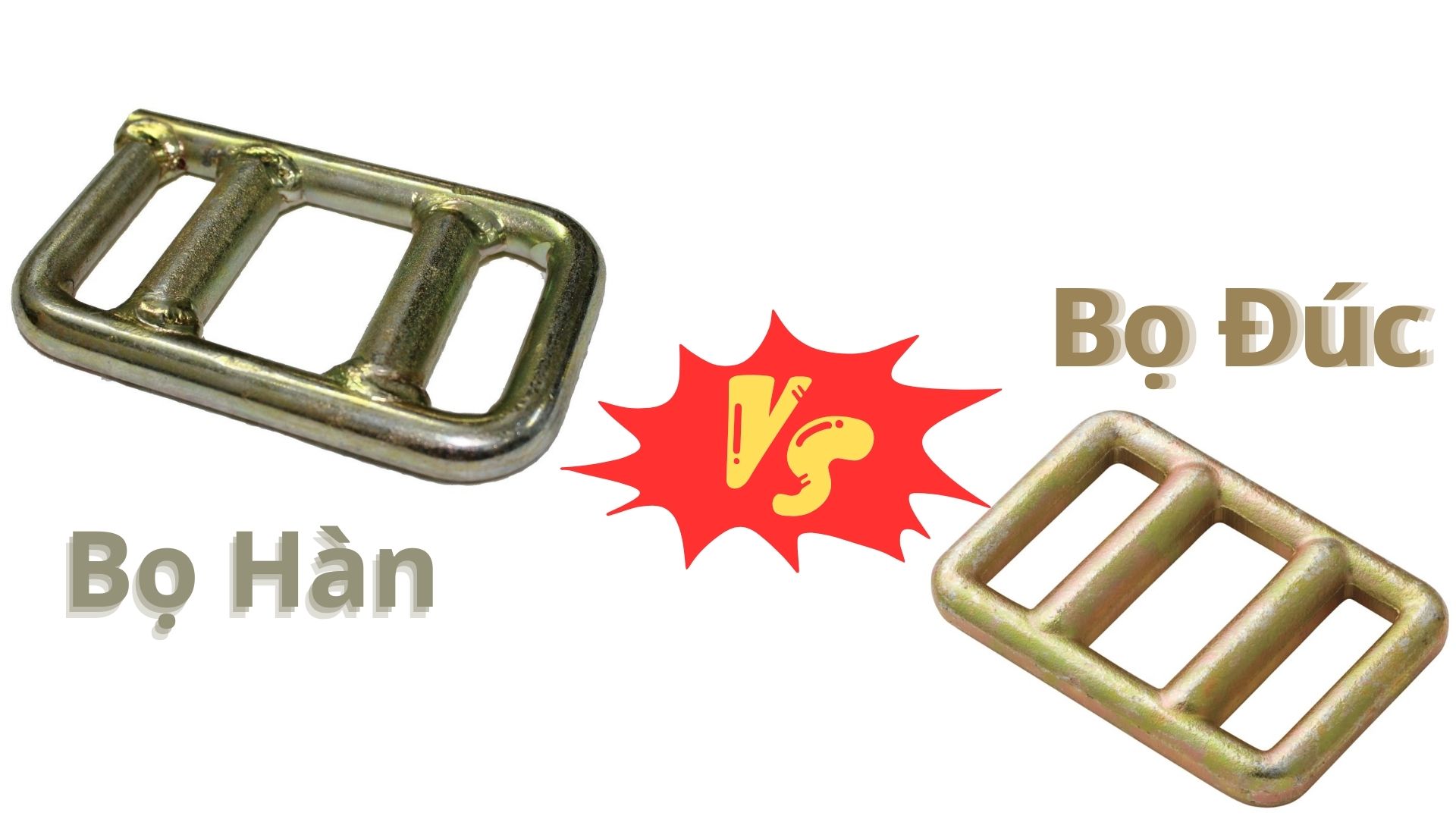

1. Molded Lashing Buckle

- Description: Manufactured as a single piece through a high-pressure die-casting process, creating a seamless and durable design.

- Sizes:

- 38mm: Suitable for medium-weight goods, with a load capacity of up to 2000kgs.

- 50mm: Used for heavy-duty loads, with a load capacity of up to 3000kgs.

- Advantages:

- High durability due to its monolithic structure.

- Exceptional strength and resistance to wear and tear.

- Maintains stability under heavy loads without deforming.

- Disadvantages:

- Heavier compared to welded lashing buckles.

- Slightly higher cost due to manufacturing complexity.

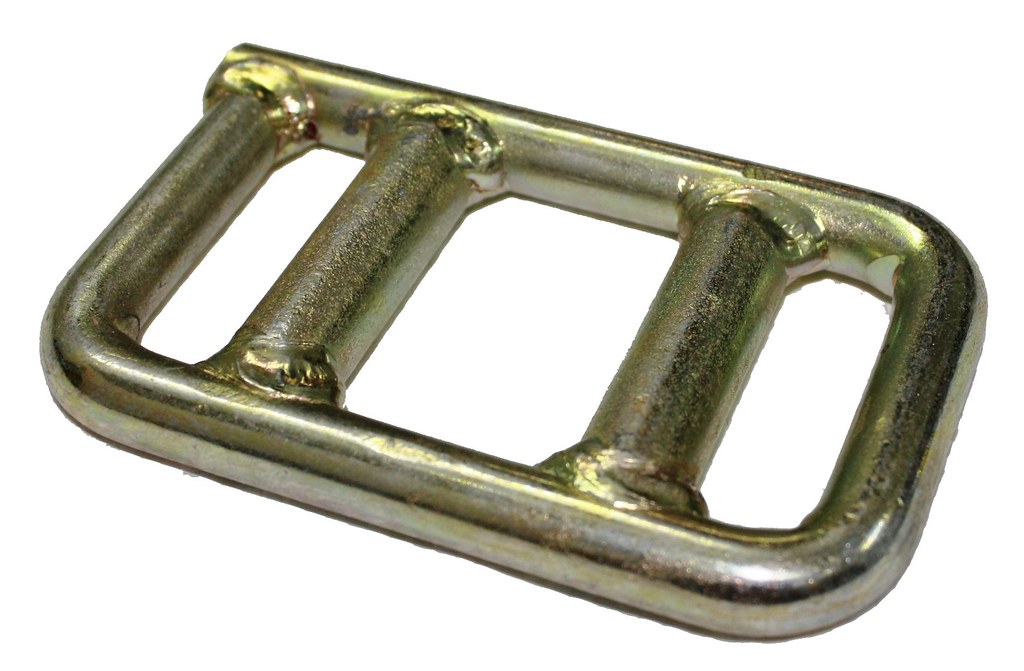

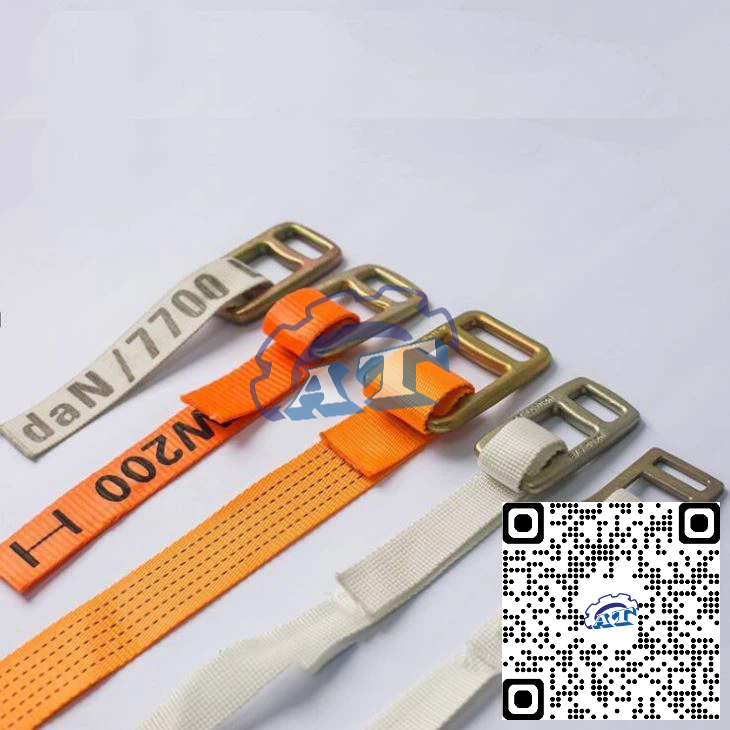

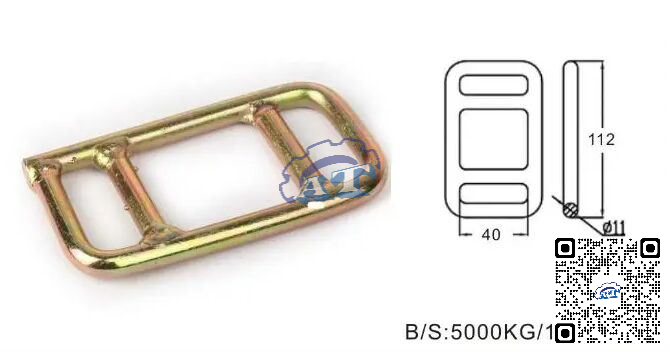

2. Welded Lashing Buckle

- Description: Created from steel or alloy bars that are bent and welded at connection points, offering a lightweight and flexible design.

- Sizes:

- 38mm: Designed for smaller goods, with a load capacity of up to 1500kgs.

- 50mm: Suitable for medium to heavy goods, with a maximum load capacity of 2500kgs.

- Advantages:

- Lightweight, making it easy to transport and handle.

- Cost-effective compared to molded buckles.

- Flexible applications for different strap sizes.

- Disadvantages:

- Less durable and prone to deformation under excessive pressure.

- Lower abrasion resistance compared to molded buckles.

Comparison: Molded vs. Welded Lashing Buckles

| Feature | Molded Buckle | Welded Buckle |

|---|---|---|

| Durability | Extremely high | Moderate, prone to bending |

| Weight | Heavier | Lightweight |

| Cost | Higher | Lower |

| Load Capacity | Best for heavy loads | Suitable for lighter loads |

| Applications | Industrial, heavy transport | Light-duty storage or transport |

Key Advantages of Lashing Buckles

- Strong Load Securing: Prevents movement and shifting during transport.

- Weather Resistant: Withstands harsh conditions, including rain, UV, and temperature changes.

- Ease of Use: Simple design for quick tightening and releasing.

- Versatility: Compatible with various lashing straps for a wide range of applications.

Practical Applications of Lashing Buckles

- Cargo Transport: Ensures goods are secure on trucks, ships, or aircraft.

- Industrial Use: Handles bulky equipment or materials like steel beams and machinery.

- Warehouse Storage: Keeps goods stable and organized in storage.

- Construction: Secures heavy building materials during transport or on-site storage

See more: Ratchet Straps, Cam Lock Straps, Heavy-Duty Tie-Downs.

There is no products in this list