Laser Cutting Services Take Center Stage: A Deep Dive into Stainless Steel Fiber Laser Cutting, CNC Laser Technology, and More Across the Globe

- The Rise of Laser Cutting Services: A Global Phenomenon

- Understanding Stainless Steel Fiber Laser Cutting: The Technology Behind the Precision

- CNC Laser Cutting Machines: Powering the Future of Fabrication

- Laser Cutting Sheet Metal Near Me: Finding Local Expertise

- A Step-by-Step Guide to Using a Laser Cutting Machine

- Step 1: Prepare Your Design

- Step 2: Set Up the Machine

- Step 3: Import and Configure Settings

- Step 4: Execute the Cut

- Step 5: Post-Processing

- Safety Tips

- Laser Cut Innovations: Applications and Inspiration

- Why Choose An Thanh Technical Co., Ltd.?

- Regional Spotlights: Laser Cutting in Action

- United States: Precision at Scale

- United Kingdom: Craftsmanship Meets Technology

- Canada: Resilience in Harsh Conditions

- India: Affordable Innovation

- Australia: Versatility Down Under

- Conclusion: Embrace the Laser Cutting Revolution with An Thanh

In an era where precision and efficiency define industrial success, laser cutting services are revolutionizing manufacturing worldwide. From stainless steel fiber laser cutting to advanced CNC laser cutting machines, this technology is transforming how businesses in the United States, United Kingdom, Canada, India, and Australia approach metal fabrication.

Published: June 25, 2025

In an era where precision and efficiency define industrial success, laser cutting services are revolutionizing manufacturing worldwide. From stainless steel fiber laser cutting to advanced CNC laser cutting machines, this technology is transforming how businesses in the United States, United Kingdom, Canada, India, and Australia approach metal fabrication. Leading this innovation is An Thanh Technical Co., Ltd., Vietnam’s largest and most trusted manufacturer of cutting-edge laser solutions. This in-depth article explores the latest trends, detailed guides, and why An Thanh is the go-to partner for industries across these vibrant markets. Whether you're searching for a laser cutter near you or curious about CNC laser cutting machine prices, this guide is designed to keep you engaged with practical insights, regional highlights, and a wealth of information.

The Rise of Laser Cutting Services: A Global Phenomenon

Laser cutting has become a cornerstone of modern manufacturing, offering unmatched precision for materials like stainless steel, sheet metal, and more. The process uses a focused laser beam to melt, burn, or vaporize materials, creating clean, intricate cuts without physical contact. This non-invasive technique suits industries from automotive to aerospace, and its adoption is growing rapidly in key regions.

- United States: With a robust manufacturing sector, the U.S. leads in demand for laser cutting services, especially for stainless steel fiber laser cutting. Cities like Detroit and Houston are hubs for automotive and energy-related fabrication, where precision is essential.

- United Kingdom: The UK’s engineering and design industries, particularly in Birmingham and Manchester, rely on laser cut solutions for bespoke furniture and industrial components.

- Canada: Known for its harsh winters and rugged landscapes, Canada’s metalworking sector in Toronto and Vancouver uses laser technology to craft durable equipment for mining and construction.

- India: India’s rapid industrialization, especially in Mumbai and Chennai, has fueled a surge in laser cutting for stainless steel and sheet metal, supporting its growing manufacturing base.

- Australia: From Sydney’s architectural projects to Perth’s mining equipment, Australia leverages laser cutters for both industrial and creative applications.

At the forefront of this global shift is An Thanh Technical Co., Ltd., a Vietnamese powerhouse that has earned its reputation as the country’s largest producer of laser cutting machines and services. With state-of-the-art facilities and a commitment to innovation, An Thanh exports its high-quality solutions to these regions, catering to diverse needs with customizable options. Explore their offerings at An Thanh’s product page.

Understanding Stainless Steel Fiber Laser Cutting: The Technology Behind the Precision

Stainless steel fiber laser cutting stands out for its ability to handle reflective metals effortlessly, thanks to the 1064nm wavelength of fiber lasers. Unlike traditional CO2 lasers, fiber lasers provide higher energy efficiency, faster cutting speeds, and minimal heat-affected zones, making them ideal for intricate designs and thick materials.

How It Works

The process starts with a fiber laser generator amplifying a seed laser through a glass fiber. This beam is then directed via mirrors and lenses to a cutting head, where it focuses on the stainless steel surface. The intense heat melts or vaporizes the metal, and a gas jet (often nitrogen or oxygen) expels the molten material, leaving a smooth edge. This technology suits thicknesses from 0.5mm to 20mm, depending on the machine’s power.

Benefits for Global Markets

- United States: American manufacturers use this for aerospace components, where lightweight yet strong stainless steel parts are critical.

- United Kingdom: UK firms leverage it for high-end kitchenware and medical devices, where hygiene and precision are paramount.

- Canada: Canadian industries apply it to create corrosion-resistant equipment for outdoor use.

- India: Indian factories employ it for cost-effective production of stainless steel furniture and automotive parts.

- Australia: Australian businesses use it for custom signage and marine equipment, thriving in coastal environments.

An Thanh Technical Co., Ltd. offers advanced stainless steel fiber laser cutting machines, designed with cutting-edge technology to meet these diverse demands. Their machines, available in power ranges from 1kW to 12kW, are tailored for both small workshops and large-scale operations. Learn more at

Tìm hiểu thêm tại An Thanh’s laser cutting services.

CNC Laser Cutting Machines: Powering the Future of Fabrication

CNC (Computer Numerical Control) laser cutting machines bring automation and accuracy to the forefront, guided by pre-programmed software. These machines are versatile, cutting not just stainless steel but also aluminum, brass, and other metals, making them a staple in modern workshops.

CNC Laser Cutting Machine Price: What to Expect

The cost of a CNC laser cutting machine varies widely based on power, size, and features. Entry-level models start at around $10,000, while industrial-grade machines with 6kW to 12kW power can exceed $100,000. Factors influencing price include:

- Laser power (e.g., 1kW for thin sheets, 12kW for thick plates).

- Worktable size (e.g., 4x8 feet for standard sheets, customizable for larger formats).

- Additional features like rotary attachments for tubes or automated loading systems.

Regional Insights

- United States: U.S. buyers often invest in high-powered models for mass production, with prices reflecting the need for durability in competitive markets.

- United Kingdom: UK customers prefer mid-range machines (2kW-4kW) for small to medium enterprises, balancing cost and capability.

- Canada: Canadian firms opt for rugged, weather-resistant models, with prices adjusted for remote site usability.

- India: Indian manufacturers seek affordable yet reliable options, driving demand for 1kW-3kW machines.

- Australia: Australian businesses favor versatile machines with rotary options for tube cutting, influencing higher-end price points.

An Thanh Technical Co., Ltd. provides competitive CNC laser cutting machine prices, offering models from 1kW to 12kW with customizable features. Their machines are engineered for longevity and precision, making them a smart investment. Check out pricing and configurations at An Thanh’s CNC machines.

Laser Cutting Sheet Metal Near Me: Finding Local Expertise

For businesses searching for “laser cutting sheet metal near me,” proximity to a service provider can save time and shipping costs. Sheet metal laser cutting is widely available, with local shops offering everything from prototyping to large-scale production.

How to Choose a Local Service

- Check Capabilities: Ensure the provider handles stainless steel and other metals you need.

- Review Equipment: Look for CNC laser cutting machines with at least 2kW power for efficiency.

- Assess Turnaround Time: Local services should offer quick quotes and delivery, often within days.

- Evaluate Costs: Compare per-square-foot rates, which typically range from $5 to $20 depending on complexity.

Regional Highlights

- United States: Cities like Chicago and Los Angeles boast numerous laser cutting shops, with An Thanh’s distributors providing support.

- United Kingdom: London and Glasgow have growing networks of laser cutters, supported by An Thanh’s UK partners.

- Canada: Montreal and Calgary offer reliable services, with An Thanh’s reach extending to these hubs.

- India: Delhi and Bangalore are emerging as laser cutting centers, with An Thanh’s affordable solutions gaining traction.

- Australia: Melbourne and Brisbane host skilled providers, enhanced by An Thanh’s export network.

An Thanh Technical Co., Ltd. collaborates with local distributors across these regions, ensuring access to top-tier laser cutting services. Contact them at An Thanh’s contact page to find a nearby partner.

A Step-by-Step Guide to Using a Laser Cutting Machine

Whether you’re a novice or a seasoned professional, mastering a laser cutter requires a clear understanding of the process. Here’s a detailed guide to get you started with an An Thanh machine:

Step 1: Prepare Your Design

- Use CAD software (e.g., AutoCAD or SolidWorks) to create your design.

- Export the file in a compatible format like DXF or DWG.

- Ensure dimensions match your material size (e.g., 4x8 feet for standard sheets).

Step 2: Set Up the Machine

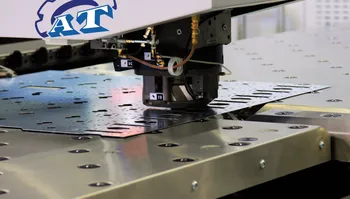

- An Thanh CNC laser cutting machine

- Load the material (e.g., stainless steel sheet) onto the worktable, securing it with clamps.

- Adjust the laser head height using the CNC controller, typically 0.5-1mm above the surface.

Step 3: Import and Configure Settings

- Upload your design file to the machine’s software.

- Set parameters: laser power (e.g., 1kW for 1mm steel, 6kW for 10mm), cutting speed (10-120m/min), and assist gas (nitrogen for clean edges).

- Preview the cut path to avoid errors.

Step 4: Execute the Cut

- Initiate the cutting process via the control panel.

- Monitor the laser as it moves, ensuring no interruptions (e.g., material shifts).

- For thick stainless steel, use multiple passes if needed, adjusting power incrementally.

Step 5: Post-Processing

- Remove the cut piece and inspect for burrs or imperfections.

- Clean the surface with a soft cloth and solvent if required.

- Store the machine by powering down and covering it to prevent dust buildup.

Safety Tips

- Wear protective goggles to shield against laser reflections.

- Ensure proper ventilation to handle fumes, especially with metals.

- Follow An Thanh’s safety guidelines available on their website.

This guide is tailored for An Thanh’s user-friendly laser cutting machines, designed with intuitive interfaces for all skill levels. Visit An Thanh’s training resources for video tutorials.

Laser Cut Innovations: Applications and Inspiration

The versatility of laser cut technology opens doors to creative and industrial applications, inspiring businesses worldwide.

Creative Uses

- United States: Artists in New York use laser cut stainless steel for sculptures and home décor.

- United Kingdom: London designers craft laser-cut jewelry with intricate patterns.

- Canada: Vancouver artisans create laser-cut wooden inlays for furniture.

- India: Mumbai craftsmen produce laser-cut wedding invitations on acrylic.

- Australia: Sydney hobbyists make laser-cut model ships from sheet metal.

Industrial Applications

- United States: Detroit automakers use laser cutting for chassis components.

- United Kingdom: Manchester factories produce laser-cut electrical enclosures.

- Canada: Calgary mines rely on laser-cut drill bits.

- India: Chennai shipyards use it for hull plating.

- Australia: Perth constructs laser-cut mining machinery parts.

An Thanh Technical Co., Ltd.machinescustom laser solutions cater to both niches, ensuring scalability.

Why Choose An Thanh Technical Co., Ltd.?

As Vietnam’s largest laser cutting manufacturer, An Thanh Technical Co., Ltd. combines cutting-edge technology with a customer-centric approach. Here’s why they stand out:

Unmatched Expertise

With over a decade of experience, An Thanh has perfected laser cutting technology, producing machines that rival global leaders. Their R&D team continuously innovates, ensuring compatibility with the latest industry standards.

Global Reach

- United States: An Thanh’s distributors in California and Texas offer localized support.

- United Kingdom: Partnerships in London ensure rapid delivery and service.

- Canada: Vancouver and Toronto benefit from An Thanh’s weather-resistant designs.

- India: Mumbai and Delhi see affordable, high-quality imports.

- Australia: Sydney and Melbourne enjoy tailored solutions for outdoor use.

Customization and Support

machinescontact team provides 24/7 assistance, including installation and training, making them a trusted partner.

Sustainability

An Thanh’s energy-efficient lasers reduce operational costs, appealing to eco-conscious businesses in all regions. Learn more at An Thanh’s sustainability page.

Regional Spotlights: Laser Cutting in Action

United States: Precision at Scale

In the U.S., laser cutting servicesU.S. distributors

United Kingdom: Craftsmanship Meets Technology

UK distributors

Canada: Resilience in Harsh Conditions

Canadian industries favor An Thanh’s rugged 4kW Canada distributors

India: Affordable Innovation

India distributors

Australia: Versatility Down Under

Australia’s diverse needs are met with An Thanh’s rotary-equipped 5kW machinesAustralia distributors.

Conclusion: Embrace the Laser Cutting Revolution with An Thanh

Laser cutting services, from stainless steel fiber laser cutting to CNC laser cutting machines, are reshaping industries across the United States, United Kingdom, Canada, India, and Australia. An Thanh Technical Co., Ltd., as Vietnam’s leading manufacturer, offers the tools and expertise to elevate your projects. Whether you’re searching for “laser cutting sheet metal near me” or evaluating CNC laser cutting machine prices, An Thanh’s solutions are designed to inspire and deliver. Dive into their world at An Thanh’s homepage and start your journey today.

laser cutter at work in the USA, showcasing precision stainless steel cuts for industrial use.Alt Text: An Thanh laser cutting machine processing stainless steel in a U.S. facility.

CÔNG TY TNHH KỸ THUẬT AN THÀNH

Địa chỉ: 32-34 Dương Công Khi, X. Xuân Thới Thượng, H. Hóc Môn

Hotline: 0942 127 028

Email: cokhi.anthanhtech@gmail.com

Xem thêm